Virtual Reality

Virtual Reality (VR) is an artificial environment created with software that submerges the user into a 360-environment allowing them the interact with the 3D world as if in a simulation.

VR is the most powerful tool to replace and simulate physical onsite training for new employees especially in core areas where even a small error can cause contamination requiring facility closure followed by intensive cleaning validation and revalidation taking months of loss of production!

VR is becoming an increasingly used educational tool as it provides more immersive job training for new workers and allows existing workers to expertise new skills or practices infrequent tasks. It also allows manufacturing workers can get acquainted with the equipment and procedures without ever setting foot inside the facilities, in addition to, giving researchers and manufacturers the opportunity to conduct experiments in life-like virtual scenarios, in a safe, controlled, measurable and repeatable way.

Benefits of using VR as a training tool

- Reduces training costs

- Allows for location flexibility

- Increases accessibility of the training to anyone at any point in time

- Enables simulating situations that may be difficult or impossible to recreate in real life, e.g. safety training.

In 2021, after recognizing the benefits of using VR as a training tool and increased use of it in the field of biotechnology and healthcare, DCVMN started to develop and offer self-paced technical VR learning courses to its members, related to laboratory and facility hands-on experiences. DCVMN is the first global organization utilizing novel VR technology to provide training in the vaccine manufacturing field.

Our VR trainings software can be downloaded from the corresponding pages that you find below, to be then installed into VR headset devices for people to conduct the full VR hands-on experience.

DCVMN Virtual Reality Training Modules

We have currently developed three VR Training Modules – the cleanroom gowning procedure, the vaccine fill-finish machine assembly and process interventions.

Cleanroom Gowning Procedure: 1 piece unit (Pico Neo 3)

Gowning is a critical component of good manufacturing practices (GMP) to ensure the sterility and safety of the medical products being manufactured. The gowning procedure should be consistent and simple to instruct, these criteria are intended to reduce the risk of microbiological, particle, and pyrogen contamination.

This training has been designed to train employees on the gowning procedure before entering a sterile environment, such as the formulation and filling floor.

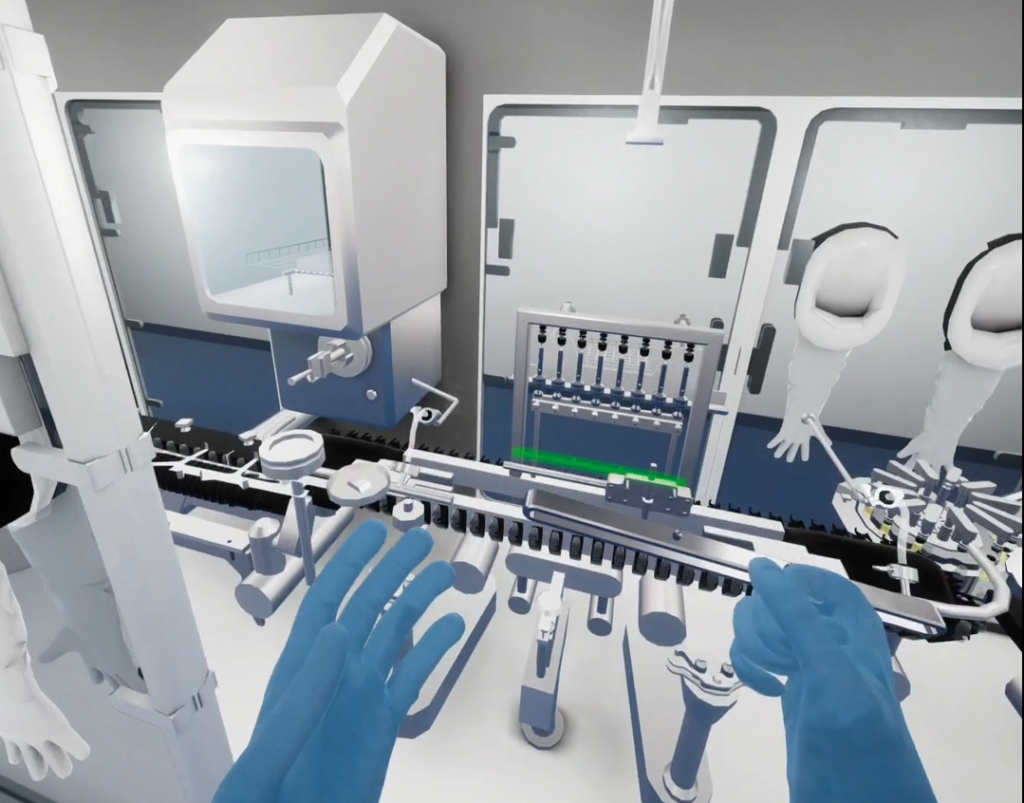

Vaccine fill-finish process: Machine assembly (Pico Neo 3)

The fill-finish process is a crucial stage in vaccine manufacturing, concentrating on the efficient formulation and packaging of products. Ensuring precision and adherence to strict sterility standards is essential for maintaining product quality and patient safety.

Our VR training module is specifically designed to train employees on this essential step, providing an immersive and interactive learning experience. This first module focuses on the assembly of the fill-finish machine, offering detailed simulations and quizzes on the following topics:

- Hand-sterilization

- Assembly of the fill-finish machine

- Testing of sterility of the fill-finish environment

Vaccine fill-finish process: Interventions taken to ensure room sterility (Pico Neo 3)

This VR training module complements our module above on vaccine fill-finish machine assembly. This second part is designed to train employees on critical interventions required during the vaccine fill-finish process. It covers essential procedures such as machine priming and addresses potential incidents like vaccine vial breakage.

This immersive training ensures that employees gain hands-on experience and a thorough understanding of the fill-finish process, enhancing their skills and performance.

These modules are integrated into a single DCVMN VR app, which can be downloaded using the link below. Once the app is installed on your VR headset, you can choose and engage with any specific VR module directly within the DCVMN app.

Regional VR Workshops – Train the Trainers

We want to better support our member companies in adopting and integrating VR technology into their employee training programs. By equipping our members’ trainers with VR know-how and familiarizing them with our modules, we’re paving the way for seamless implementation in their facilities, ready to train employees effectively and efficiently. Plus, our workshops offer the opportunity to connect with other member companies who’ve already embraced VR in their training programs, sharing insights and success stories. We have had our first workshop in India in August, and we would like to see the interest of our members from other regions to bring the workshop to them.

Do You Want to Collaborate and Create a New VR Module?

DCVMN takes care when it comes to funding, development, testing, and all the intricate details involved in creating our cutting-edge VR modules. To make it all happen, we partner closely with our VR developer.

What we ask from our members is support in the actual content of the VR module, we do not hold the same expertise as you in the different manufacturing procedures, therefore we ask our collaborating member to propose a QA or other expert on the chosen topic. This expert plays a pivotal role by providing us with detailed step-by-step instructions, along with essential visuals such as pictures and videos. Before we begin working together, we will sign a Tri-Partite NDA to protect all the information you will be sharing with us. Your expertise fuels the content creation process. After the module is developed, we loop back to our member expert. We ask them to either watch a recording or immerse themselves in the module firsthand. Their keen eye and hands-on experience enables them to provide invaluable feedback, ensuring the module’s accuracy.

Would you be interested in collaborating with DCVMN to create a new VR module?

Contact: a.marini@dcvmn.net

VR Comment/inquiry

"*" indicates required fields